As a term, warehouse has traditionally conjured massive facilities for storage, possibly trafficked by forklifts. Trucks at loading docks, and people packing boxes. But before 2020, general interest in these places and their relationship to our supply and demand system likely ended there.

Then came the pandemic. With the availability of goods suddenly of critical, global importance, with masks and cleaning products in short supply, grocery store shelves emptied, cars and computers stuck unbuilt and lacking for parts, the seemingly magical flow of logistics that constitutes supply chain became a household concern.

It also became a very real pain point for businesses everywhere.

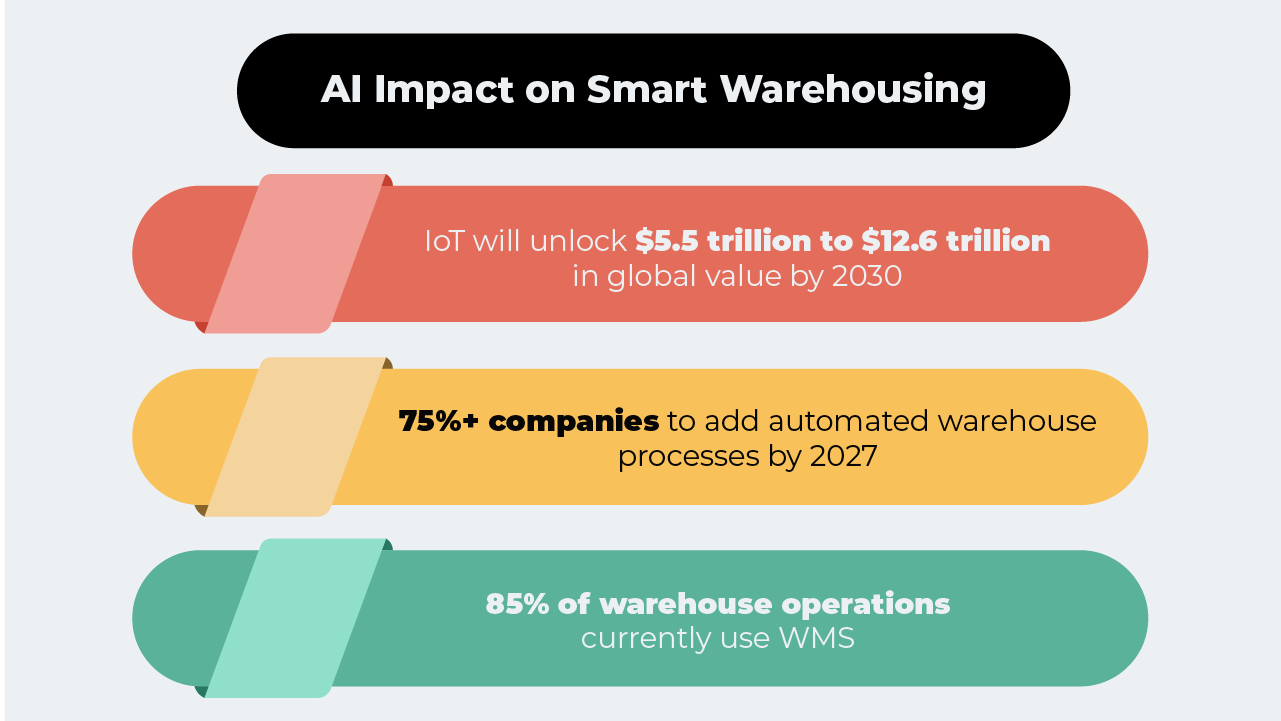

According to DHL, only 5% of warehouses are fully automated, with 15% more semi-automated, as by conveyors for picking and placement. This leaves 80% of warehouses still largely manual, though most (see below) do use some form of warehouse management software (WMS).

And with 75% of companies surveyed by Gartner planning to add automation between now and 2027, it’s clear lessons have been learned—both from the pandemic and the ensuing boom in ecommerce.

In today’s PTP Report we look at warehouse automation advancements: the transformations that are moving warehousing from storage spaces to proving grounds, and even entire ecosystems—incorporating robots and drones, digital twins, internet of things (IoT) technology, and AI-enhanced warehouse management systems (WMS).

Warehouse Robotics and AI

Automation in warehousing—even robotics in warehouses—isn’t new, but before AI, it was far less practical.

Without the ability to adapt on the fly, using automated guided vehicles (AGVs), which follow pre-set routes and routines, may have been more attainable than more flexible autonomous mobile robots (AMRs). These adapt to environment, avoid collisions, and work to multiple ends, but often at a far higher cost.

With the goal of automating material handling processes, these robotic solutions allow organizations to recoup investment costs by reducing transportation time (in-house), improving safety, and keeping a better control of inventory.

AI is beginning to break into this space in a big way, via companies like Covariant, recently raising more than $222 million in funding and launched by three former OpenAI researchers. As profiled by the New York Times, Covariant:

- Enables warehouse robotic interface as chat ala chatbots.

- Can pick up and move items of varying kinds around varying warehouse arrangements.

- Doesn’t built their own robots, but brings AI and advanced operations to robotics.

- Uses multimodal AI training, allowing robots to understand the physical world beyond their programming. In a test, a Covariant robot knew how to pick up a banana, despite never having seen one.

- Can generate videos before attempting something, to show users what’s likely to happen.

- Also works on advanced sorting robots that learn by trial and error.

Another company working to integrate AI and warehousing technology is Pittsburgh-based Gather AI. Begun by graduate students at Carnegie Mellon’s Robotics Institute, Gather recently made headlines by securing $17 million in additional funding to scale up their existing operations. These include:

- Constructing a platform that uses autonomous drones to track warehouse products.

- Customers include: third-party logistics, retail, food and beverage, and manufacturing.

- Makes extensive use of AI-powered cameras.

CEO Sankalp Arora says: “AI-powered cameras will transform supply chain traceability to have a similar impact that barcodes did in the 1980s, and our technology is at the forefront of this transformation.”

In addition to improving warehousing efficiency, AI-driven robotics can be more safely tested in these spaces.

With human and robotic workers operating in varying shifts, warehouses can make the ideal spaces to test AI-driven robotics such as AMRs, where the stakes for catastrophic failure are far lower and interactions can be more safely controlled until they’re ready for more.

Digital Twins Mirror the Physical World

As with other facilities of scale, warehouses make excellent spaces for the implementation of digital twin technology.

Virtual replicas of warehouses can be invaluable for warehouse ecosystem optimization, going beyond just 3D-mapping with real-time data, to incorporate full processes and workflows. By running speculative configuration changes through a digital twin, for example, experimentation can be done risk-free, allowing for far greater efficiency and shorter implementation time.

When used alongside robotic innovations (as above, for example), digital twins can give immediate answers to a new technology’s impact, practically and financially, without disrupting the current operations.

IoT: Connecting It All Together

With sensors increasingly embedded on everything from the vehicles used in transportation, to containers, pallets, and forklifts, collecting and using all this available data becomes increasingly essential in supply chain optimization.

Radio Frequency IDentification (RFID) tags with integrated circuits (or simpler smart labels) can provide real-time tracking, helping to improve inventory accuracy.

The connectivity enabled by IoT, with data from sensors and smart cameras, and real-time update capacity, can be essential sources for feeding AI-enhanced warehouse management solutions.

The Evolution of Warehouse Management Software

The most common smart-warehousing technology with mass adoption is the warehouse management system (WMS), which is also undergoing a transformation with the widespread arrival of AI. WMS is increasingly doing far more than spreadsheets or databases for recording inventory, instead acting with intelligence and even predictive analytics to influence decision-making now and into the future.

Smarter WMS software solutions can increasingly assist with:

- Inventory management (the traditional backbone of WMS improved, for tracking stock, storage, minimize costs)

- Order fulfillment (with the innovations above, can add automated pick and pack, with reduced errors)

- Task/labor management (allocating workforce, using analysis to take peak times into account well ahead of need)

- Predictive data analytics for warehousing (forecast demand changes, using the past as a guide)

- Enhanced logistics efficiency (analyzing current routines and workflows)

- A shift towards the cloud makes these systems increasingly scalable, flexible, and cost-efficient even for smaller organizations. [Check out this PTP Report for more on cloud trends and impact in 2024 and beyond!]

- Direct integration with other systems (ERP, transportation management, personnel management and more)

- Greater customization than ever-before (allowing more efficiency within specific implementations)

- Far-friendlier interfaces, with improved accessibility and a lower-bar for access, to improve training -times and productivity

The better the WMS, the less inventory is lost: incorporating technology like that provided by Gather AI (above), drones with smart-cameras scan inventory directly, feeding the system with accurate information in real-time.

AI in warehouse management systems can aid with layout and process improvement, and using digital twin technology (above), even tested virtually, before implementation, radically reducing waste.

Conclusion

As we move into the AI-powered future, backed by the surge in ecommerce and lessons learned in the pandemic, warehouses are no longer just massive storage centers.

Instead, they can be vital components in smarter supply chains, hubs with greater potential for transparency, efficiency, and safety than ever before. They can also be testing grounds for AI robotics across industries, with the ability to work from more repetitive routines, in more tightly controlled environments.

Whether driven by ecommerce, supply chain disruptions, or labor shortage, it’s a great time to embrace this opportunity: reducing waste, cutting costs, and improving efficiency across the board.

References

The accelerating value of the Internet of Things, McKinsey

Gather AI secures new cash to scan inventory in warehouses using drones, TechCrunch

A Warehouse Robot Learns to Sort Out the Tricky Stuff, New York Times

RFID (radio frequency identification), TechTarget

The Secret Weapon Of Smart Warehouses & Data Centers? Generative AI, Forbes